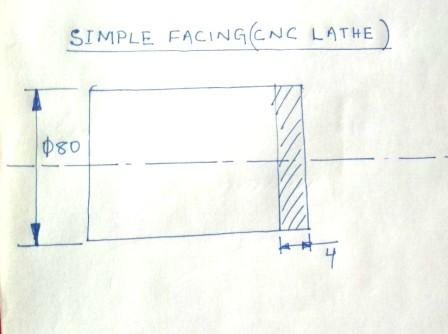

CNC facing program-Simple Facing CNC Lathe Program Example.-Fanuc

O0001(CNC Facing Program)

N1;

T0;

G40;

G28 U0 W0; -(X-U,Z-W)

G92 S1000;

G95 F0.2 T0101;

G96 S280 M04;

G00 Z5.0;

G00 X82.0;

G01 Z2.0 ;

G01 X0.0;

G1 Z3.0;

G00 X82.0;

G01 Z0.0;

G01 X0.0;

G1 Z1.0;

G00 X200.0;

T0;

G28 V0 W0;

M01;

M30;

Explanation for facing program

| N1; | Sequence Number. |

| T0; | Tool wear cancel. |

| G40; | Cancelling G41 & G42. |

| G28 U0 W0; | Home Position. |

| G54; | Work co ordinate. |

| G92 S1000; | Limiting speed. |

| G95 F0.2 T0101; | Feed & Tool. |

| G96 S280 M04; | Cutting Speed & spindle Rotation |

| G00 Z5.0; | Tool will move to Z5.0 rapidly.This is the safety distance.(Z5.0 is the safety distance because here Work coordinate is set Z0.0 at final face.That is from final face raw material is 4.0 more which is need to face.If we will take Z0.0 at raw material face then we have to face upto -4.0.) |

| G00 X82.0; | In this block tool will move to X82.0 rapidly.This is the safety distance for x axis. |

| G01 Z2.0; | Now tool will move to Z2.0.This distance is to face. |

| G01 X0.0; | Now tool will move to X0.0 in feed.This movement will remove 2mm material . |

| G1 Z3.0; | Safety distance in Z axis i.e Z3.0. |

| G00 X82.0; | Tool will move to safety distance in X axis i.e. X82.0. |

| G01 Z0.0; | Now tool will move to Z0.0 which is the final face setted in G54(Work coordinate).This movement is to face another 2mm . |

| G01 X0.0; | This movement will remove material /face 2mm.Facing is completed now. |

| G01 Z1.0; | Tool will move to safety distance in Z axis. |

| G00 X200.0; | Tool will move to a safety distance X200.0. |

| T0; | Cancel tool wear. |

| G28 V0 W0; | Home position. |

| M01; | Optional stop. |

| M30; | Program stop. |

We need to set Work coordinate ,tool geometry and tool wear before program start.

Learn basic of programming

- Turning programming,

- Taper turning,

- Grooving,Radius,

- Turning cycle and

- facing cycle.

Learn Automation-Click here.

0 Comments