This is the basic of CNC Programming .Here you will get a complete idea about the programming for CNC machine.Here you will learn about the codes,defining part of the program,Operation part of the program and closing part of the program.You will learn about some simple example of programming.

| Facing program | Turning program | Taper turning program |

| Grooving Program | Radius program | Turning cycle & Facing cycle |

Basic of CNC programming is to learn about G codes ,M codes and all the steps.It is to learn about all steps of a program to complete a machining process.

Basic of cnc programming codes

Language of CNC machines

- G code

- M code

CNC machine language which control the movement of axis /Tools.

CNC machine language which control the machine function.

Here we are going to learn about Basic programming of FANUC (Oi-TB)and SIEMENS(802d/802dSL/828d).

Siemens G code list-802d

| Codes | Function |

| G00 | Linear interpolation at rapid traverse rate |

| G01 | Linear interpolation at feed rate |

| G02 | Circular interpolation clockwise |

| G03 | Circular interpolation counter clockwise |

| G04 | Dwell time |

| G18 | Z,X-Plane(Standard turning) |

| G33 | Thread cutting with constant lead |

| G40 | Tool radius compensation off |

| G41 | Tool radius compensation left of contour |

| G42 | Tool radius compensation right of contour |

| G53 | Settable work- offset–Non- modal skipping |

| G54 | 1st settable work offset |

| G55 | 2nd settable work offset |

| G56 | 3rd settable work offset |

| G57 | 4th settable work offset |

| G58 | 5th settable work offset |

| G59 | 6th settable work offset |

| G71 | Metric dimension data input |

| G90 | Absolute dimension data input |

| G91 | Incremental dimension data input |

| G95 | Feed rate F in mm/Spindle revolutions |

Siemens M code list-802d

| Codes | Functions |

| M00 | Programmed stop |

| M01 | Optional stop |

| M02 | End of the program with return to program start |

| M03 | Clockwise rotation of spindle |

| M04 | Counter clockwise rotation of spindle |

| M05 | Spindle stop |

| M08 | Coolant ON |

| M09 | Coolant OFF |

| M30 | End of program(as M02) |

Fanuc G codes-Series Oi-TB

| Codes | Function |

| G00 | Rapid traverse |

| G01 | Linear interpolation |

| G02 | Circular interpolation-CW |

| G03 | Circular interpolation-CCW |

| G04 | Dwell command |

| G10 | Programming data input offset |

| G20 | Outer/inner dia cutting cycle |

| G21 | Thread cutting cycle |

| G24 | End face turning cycle |

| G27 | Reference point return check |

| G28 | Reference point return |

| G33 | Threading |

| G40 | Tool nose radius comp. Cancel |

| G41 | Tool nose radius comp.Left |

| G42 | Tool nose radius comp.right |

| G53 | Cancel work offset |

| G54 | Work coordinate system 1 (optional) |

| G55 | Work coordinate system 2 (optional) |

| G56 | Work coordinate system 3 (optional) |

| G57 | Work coordinate system 4 (optional) |

| G58 | Work coordinate system 5 (optional) |

| G59 | Work coordinate system 6 (optional) |

| G65 | Macro calling |

| G70 | Inch programming(Optional) |

| G71 | Metric programming (optional) |

| G72 | Finishing cycle( optional) |

| G73 | Stock removal in turning(Optional) |

| G74 | Stock removal n facing(Optional) |

| G75 | Pattern repeating(Optional) |

| G76 | Peck drilling in z axis (Optional) |

| G77 | Grooving in X axis (Optional) |

| G78 | multiple thread cutting cycle(Optional) |

| G90 | Absolute programming |

| G91 | Incremental programming |

| G92 | Position preset & spindle speed clamp in css mode during S word. |

| G94 | Per minute feed |

| G95 | Per revolution feed |

| G96 | Constant surface speed |

| G97 | Direct RPM programming |

Fanuc M codes-Oi-TB

| Codes | Function |

| M00 | Program stop |

| M01 | Optional stop |

| M02 | End program |

| M03 | Spindle ccw |

| M04 | Spindle cw |

| M05 | spindle stop |

| M08 | Coolant ON |

| M09 | Coolant OFF |

| M10 | Chuck /Collet Close |

| M11 | Chuck / Collet Open |

| M12 | Low chucking pressure(Optional) |

| M13 | High chucking pressure(Optional) |

| M18 | Tailstock swing IN(Optional) |

| M19 | Tailstock swing OUT(Optional) |

| M20 | Quill LEFT(Optional) |

| M21 | Quill RIGHT(Optiional) |

| M22 | Turret Index reverse |

| M23 | Turret index Forward |

| M24 | Steady rest-1 Open(Optional) |

| M25 | Steady rest-1 Close(Optional) |

| M26 | Steady rest-2 Open(Optional) |

| M27 | Steady rest-2 Close(Optional) |

| M28 | parts catcher open(Optional) |

| M29 | Parts catcher Closr(Optional) |

| M30 | Program reset and rewind |

| M36 | Cancel M37 |

| M37 | Ignore upto speed feedhold signal |

| M40 | Dry run spindle OFF |

| M41 | Dry run spindle ON |

| M42 | Dry run cancel |

| M48 | Cancel M49 |

| M49 | Feed rate and Spindle speed overrides inactive |

| M62 | Spindle Hold OFF |

| M63 | Spindle Hold ON |

| M76 | Low quill pressure ON(Optional) |

| M77 | Low quill pressure OFF(Optional) |

| M78 | Select quill zero pressure(Optional) |

| M90 | In position check ON |

| M91 | In position check OFF |

| M92 | Soft jaw boring |

| M98 | Sub program call |

| M99 | Sub program end |

Programming systems

There are two types of programming mode used in CNC.

- Absolute

- Incremental

Incremental progamming mode(G91)

This is the programming mode where the movement (tool/bed/spindle) based on its last(Current) position.

Absolute progamming mode(G90)

This is the programming mode where all the movement measures from Origin point.

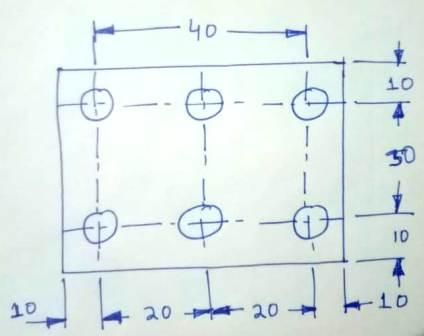

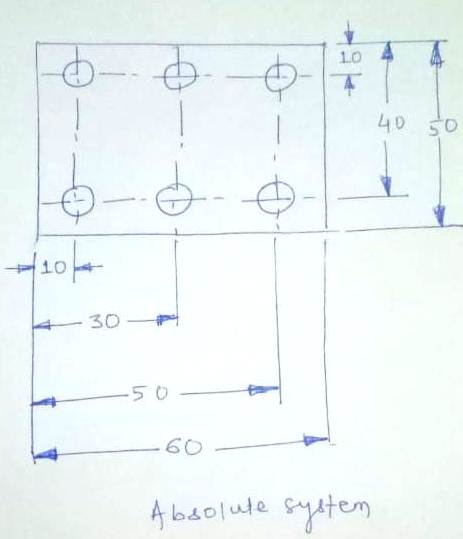

Difference between absolute and incremental programming in CNC

Incremental Dimension

Absolute dimension

CNC Positioning System

- Point To point

- Continuous path(contouring)

Point to point Positioning

Positioning(tool/spindle/Bed) from one coordinate(X,Y) to another to perform operation like drilling,Boring,reaming,taping..etc.

Continuous path(contouring)

The cutting tool travel from one point to another in Contact with work piece .Example- Turning .Milling

Zero Point Setting

Zero point can be set by any one method.

- Operator

- Manually by program

- Work coordinate

What is work offset in CNC?

This is also called work coordinate.This method is used to set zero point of the machine.Example- G54 X_ Z_.This is for master tool only.For other tool we need to set the tool geometry.

How to set work offset in CNC?

Practical of Work offset setting.-Touch the tool tip on face of raw material/workpiece and go to work offset G54 and set the Z value 0.0.Again touch the tool tip on OD of the work piece and set the X value .That is OD value.

What is Tool geometry offset in CNC?

This is the work offset for individual tool.Work offset required for other tool to perform the different operation.

What is Tool wear offset in CNC?

This offset is used to compensate tool wear.For example if there is 0.1mm of material remain after finishing cut.Then we need to input -0.1 in tool wear section and again to run the finishing cut program to remove remain material.

Interpolation

This method is the movement of Cutting tool from one point to another.

- Linear

- Circular

- Helical

- Parabolic

- Cubic

Linear Interpolation(G00/G01)

In this method the cutting tool move in a straight line.

Circular Interpolation(G02/G03)

In this method the cutting tool moves as circle or arc.This is of two types.Clockwise and counter clockwise

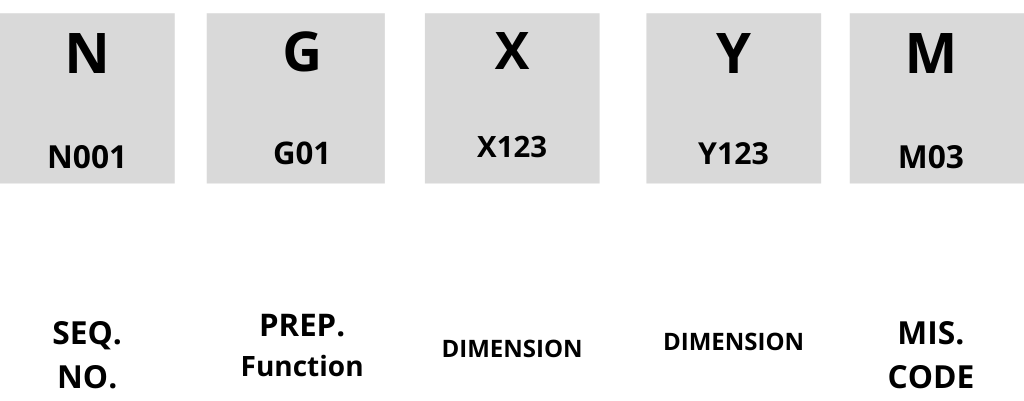

Block(CNC information)

Its consists of 5 word written in Horizontal line.This is recognized by MCU((Machine control Unit).

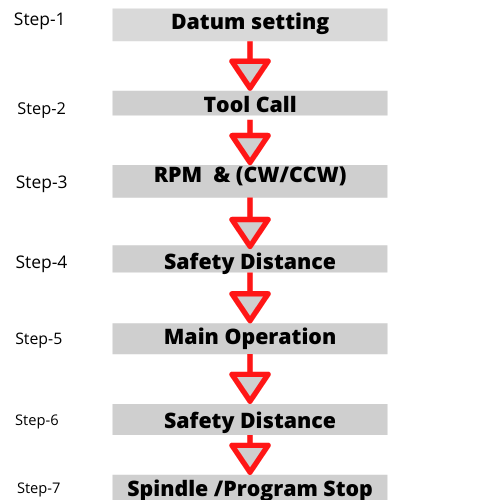

How to cnc programming

Step-1 : DATUM SETTING

Example:-

G00 G54 G90 G95 X_ Z_;

Step-2 : TOOL CALL

Example;-

T1 D1;

Step-3 : Spindle/Chuck-RPM & Direction

Example:-

M03 S90 ;

Step-4 : Safety Distance

Bring the Tool to a Safety Distance

Step-5 : Main operation

Example:-Turning/Facing/Grooving/Chamfer/Radius

G01 X_ Y_;

Step-6 : Safety Distance

Return the tool to a safety distance.

Step-7 : Spindle /Program Stop

Example:- M05 M30;

CNC programming example-fanuc(Lathe)

O0001(PLAIN TURNING)-Fanuc

N1; Sequence number

T0; Tool wear cancel

G40; Cancelling G41 & G42

G28 U0 W0; Home position

G54; Work coordinate

G92 S1000 ; Limiting speed

G95 F0.2 T0101; Feed & Tool

G96 S250 M04; Cutting speed & Spindle Rotation

G00 Z 3.0; Safety distance for Z axis.-Rapid

G00 X 56.0; Safety distance for X axis-Rapid

G1 X 50.0 M08; Turning operation & Coolant ON

G01 Z -40; Turning Operation.

G1 X 56.0; After turning operation tool will return to safety distance in feed.

G00 X 200 M09; Return to safety distance in Rapid & coolant OFF

T0;

G28 U0 W0; Return to home position

M01; Optional stop

M30; Program reset

CNC programming example-Siemens(Lathe)

G0 G54 G90 G94 X120 Z2; Datum setting & rapid movement of a tool to a safety distance X120 and Z2

T1 D1 ; Tool Selection

M03 S90 ; Speed and direction

G0 X60 Z2 ; Safety distance

G1 X50 Z0 F0.3; Starting point & feed

G1 X50 Z-220; Turning

G1 X80 Z-220; Turning

G1 X80 Z-565; Turning & end point

G1 X100 F0.4 ; Tool safety

G0 X120; safety distance

G0 Z2; Safety distance

M05 M30; Spindle stop & Program end

CNC programming lathe

Before learning about cnc programming for lathe machine we should know about the Cartesian Coordinate system.From which we can find out the coordinate point for any work piece.We should also learn about WORK CO-ORDINATE,TOOL GEOMETRY,TOOL WEAR.

CNC programming Facing

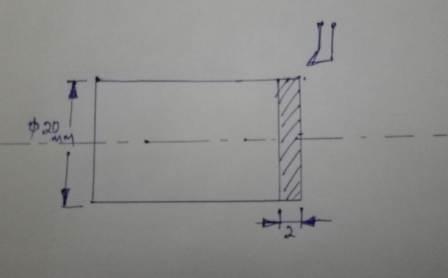

Raw material size – Diamter-20,Lenght- Any. If we want facing for 2 mm.

G0 X21.0 Z0.5 ; – Safety distance(Tool will move to 21.0 point in X axis and 0.5 in z axis rapidly ).20.0 is the diameter of raw material and face of work piece is the Z0.0.Tool will stop at Z 0.5 which is the distance from face.This is the suitable safety distance for raw material.After this it will start facing.

G01 Z-1.0 F0.3; – Tool will move to Z -1.0 in feed (Feed you can change)

G01 X 0.0; – Tool will move to X0.0 in feed .This is the facing operation of tool.As the tool start removing material from Z-1.0 to X0.0.That means 1.0 mm of material remove from face of the work piece.

G01 Z0.5; Now tool will move to Z 0.5 in feed.

G00 X21.0; Tool will move rapidly move to X21.0. Next to perform another facing operation.

G01 Z-2.0; Tool will move to Z-2.0 so that it can remove another 1.0 mm material

G01 X0.0; Tool will remove 1.0 mm of material from face of the work piece in this movement.

Now we can again move the tool to Z 0.5 in feed and then X21.0 in rapid.We can use the facing cycle to perform the facing operation.There we have to set the dimension to face and feed.The facing cycle will remove the material as per your requirement.

Basic of CNC programming Turning

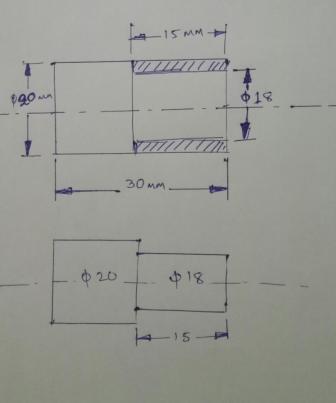

If the Raw material having diameter 20 and lenght 30. and we want to make it of diameter 18 upto lenght 15mm.

G00 Z3.0; – This is the safety distance for Z axis i.e tool will move rapidly and stop at Z3.0.Which is the distance from face.(As face of workpiece is taken Z0.0)

G00 X22.0; – This is the safety distance for X axis.

G01 X19.0; – The tool will move to 19 diameter in X axis in feed. .(This movement is for turning of 1mm i.e upto 19 diameter)

G01 Z-15; – This is the Turning operation.Tool will move from X19.0 to Z-15 with removing material.(Here you can turn ON the coolant)

G01 X22.0; – Tool will move to safety distance of x axis.

In this way you can turn another 1mm.This is the way for turning operation.

Learn Hydraulics-Click here.

Learn about Solenoid valve-Visit here.

CNC Operation & Maintenance

- CNC LATHE MACHINES (28)

- CNC MILLING MACHINE (4)

- CNC Programming (13)

- Maintenance (45)

- Maintenance of CNC machine (73)

- Operation (17)

- Workshop Technology (22)

Automation CNC practical CNC theory Electrical Fanuc CNC Programming Hydraulic Pneumatics Siemens CNC programming

0 Comments