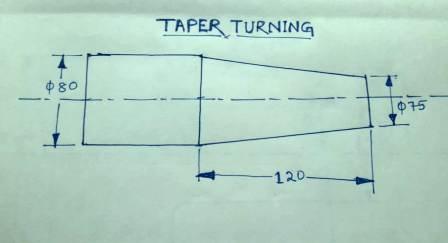

CNC program for taper turning pdf-Learn CNC program for taper turning for both Fanuc and Siemens.

Program-Taper turning cnc code- Oi-TB

O0005(Taper turning);

N1;

T0;

G40;

G28 U0 W0;

G54;

G92 S1000;

G95 F0.2 T0101;

G96 S180 M04;

G00 Z2.0;

G00 X82.0 M08;

G01 X75.0;

G1 X80.0 Z-120;

G01 X82.0;

G00 Z2.0;

G00 X300.0 M09;

G28 U0 W0;

T0;

M01;

M30;

Taper turning Program Explanation

| Codes | Explanation |

| N1 | Sequence number. |

| T0 | Tool wear cancel.This will cancel the previously entered tool wear. |

| G40 | Cancelling G41 & G42. This will cancel tool radius compensation left and right. |

| G28 U0 W0 | Home position.U =X,W=Z. |

| G54 | Work co-ordinate. |

| G92 S1000 | Limiting Speed. |

| G95 F0.2 T0101 | Feed is 0.2 per revolution. T0101 is the tool . |

| G96 S180 M04 | Cutting speed.Spindle rotation.(CW) |

| G00 Z2.0 | Rapid movement of tool to Z2.0 position. Safety position for Z axis. |

| G00 X82.0 M08 | Rapid movement of too to X82.0. Safety position for X axis as diameter of raw material is 80. Tool will move rapidly to 82.0 diameter. M08 is Coolant ON. |

| G01 X75.0 | Tool will move to 75 diameter in feed. This movement is for taper turning starts at 75.0 diameter.In next step is turning. |

| G01 X80.0 Z-120 | This is the taper movement of tool from (75.0,0.0) to (80.0,-120.0). In X axis tool will lift upto 80 diameter and in Z axis too will move upto -120.0. |

| G01 X82.0 | Tool will move to safety distance in X axis. |

| G00 Z2.0 | Rapid movement of tool for safety distance in Z axis. |

| G00 X300.0 M09 | Rapid movement of tool to safety distance 300 diameter. M09- Coolant Off. |

| G28 U0 W0 | Home postion. |

| T0 | Tool wear cancel. |

| M01 | Optional Stop. |

| M30 | Program reset & recycle. |

As turning of 5mm diameter is not possible at a time we need to use turning cycle.

0 Comments