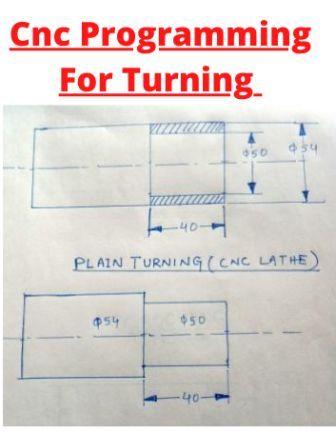

CNC programming examples for turning-CNC Programming for Turning.This is the basic example of turning programming.Beginners can get the complete idea about the turning operation.

Program(Fanuc Oi-TB)

O0001(Plain Turning);

N1;

T0;

G40;

G30 P3 U0 W0;

G54;

G92 S1000;

G95 F0.2 T0101;

G96 S250 M04;

G00 Z3.0;

G00 X56.0;

G01 X50.0 M08;

G01 Z-40.0;

G1 X56.0;

G00 X200 M09;

T0;

G28 U0 W0;

M01;

M30;

Program Explanation-

| N1 | Sequence number. |

| T0 | Tool wear cancel. For details of Tool wear read-Basic of cnc programming |

| G40 | Cancelling G41 & G42. |

| G30 P3 U0 W0 | Home position. P3-position,U=X axis,W=Y axis. |

| G54 | Work coordinate. |

| G92 S1000 | Limiting speed. |

| G95 F0.2 T0101 | Feed & Tool. |

| G96 S250 M04 | Cutting speed & spindle rotation. |

| G00 Z3.0 | Safety distance for Z axis. Tool will move rapidly to Z3.0. That is tool will stop at a distance 3.0 from face. |

| G00 X56.0 | Safety distance for X axis. Tool will move rapidly to 56 diameter. As the diameter of raw material is 54. |

| G01 X50.0 M08 | Tool will move in feed to 50 diameter. M08-Coolant ON. |

| G01 Z-40.0 | This is the turning movement of tool upto Z-40.0 as per drawing. |

| G01 X56.0 | Tool will return to safety postion with feed. |

| G00 X200 M09 | Tool will move to a safety distance of 200 diameter. M09- Coolant ON. |

| T0 | Tool wear cancel. |

| G30 P3 U0 W0 | Home position. |

| M01 | Optional stop. |

| M30 | Program stop and recycle. |

0 Comments