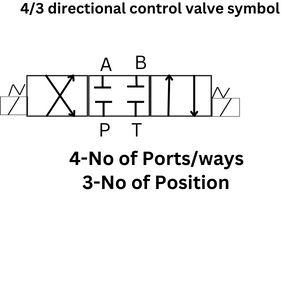

3 position 4 way valve symbol or 4/3 directional control valve symbol.

It has 4 ports/ways-P,T,A and B. P is pressure port.T is tank.A and B connected to cylinder.

Center position is close type.

During middle position all ports are closed.

In right position P is connected to A and B is connected to Tank.In this position piston will move forward.

During left position pressure connected to B and A is connected to tank.Here piston will move backward.

For CNC Programming click here.

- Power Electronics application and ScopeSome factors expand the demand of Power Electronics application are-. Energy conservation Transportation Process control and factory automation Switch mode power supply Uninterruptible power supplies Applications Aerospace Industry Resident Transport Commercial Telecommunication Utility

- Dry run in CNC | Dry run M41 Spindle ONDry run in CNC is a program testing process.In this process all axis movement will be tested according to program.During this process spindle or chuck will not rotate. The programmer will manually test the program/code Read more…

- CNC turning | CNC turning lathe machineCNC turning machine & tools.What is turning.Types of turning. What is turning? Turning is a cutting action for external surface.In this process the cutting tool move linearly while the work piece rotates. Same cutting action Read more…

- Codes for CNC | CNC Lathe | Codes for CNC programmingCodes for CNC.Commands in CNC machine.Modals-N,G,X,Z,F,S,T,M.Non modals-U,W,I,K,R. The control will execute modal functions until the control is reset or another command cancel it. The non modal commands automatically cancels after the control executes the program Read more…

- CNC facing cycle program

CNC facing cycle program.Fanuc Oi-TB facing cycle.Siemens 802d Facing cycle program. Parameter/Code Details T1 D1 Tool number. F Feed-mm/rev. S M3 RPM,M3 -Clockwise,M4-Counter clockwise. Mach. Machining-Roughing/Finishing. DM Diameter of Job/work piece. Z0 Starting point of Read more…

CNC facing cycle program.Fanuc Oi-TB facing cycle.Siemens 802d Facing cycle program. Parameter/Code Details T1 D1 Tool number. F Feed-mm/rev. S M3 RPM,M3 -Clockwise,M4-Counter clockwise. Mach. Machining-Roughing/Finishing. DM Diameter of Job/work piece. Z0 Starting point of Read more… - CNC turning cycle program

CNC turning cycle program

CNC turning cycle program - Radius program in CNC | CNC Lathe Programming

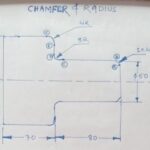

Learn Radius program in CNC. CNC turning..Fanuc cnc lathe programming examples.Siemens cnc lathe programming examples. CHAMFER COORDINATE(X,Z) RADIUS COORDINATE(X,Z) A:(48,0)B:(50,-1) C:(50,-75)D:(60,-80)E:(92,-80)F:(100,-84) PROGRAM O0007(RADIUS & CHAMFER)N1;G40;T0;G30 U0 W0;G54;G92 S1000;G95 F0.2 T0101;G96 S220 M04;G00 Z2.0;G00 X55.0 M08;G01 Read more…

Learn Radius program in CNC. CNC turning..Fanuc cnc lathe programming examples.Siemens cnc lathe programming examples. CHAMFER COORDINATE(X,Z) RADIUS COORDINATE(X,Z) A:(48,0)B:(50,-1) C:(50,-75)D:(60,-80)E:(92,-80)F:(100,-84) PROGRAM O0007(RADIUS & CHAMFER)N1;G40;T0;G30 U0 W0;G54;G92 S1000;G95 F0.2 T0101;G96 S220 M04;G00 Z2.0;G00 X55.0 M08;G01 Read more… - CNC lathe grooving program | CNC Programming For Beginners

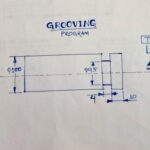

CNC lathe grooving program.Fanuc cnc programming for Grooving.CNC lathe programming. O0006;(Grooving)N1;T0;G40;G28 U0 W0;G54;G92 S200;G95 F0.06 T0909;G96 S120 M04;G00 Z-14.0;G00 X102;G01 X95 M08;G00 X300.0;T0;G40;G28 U0 W0;M01;M30; Explanation-cnc programming g code & M codes-CNC lathe grooving program Read more…

CNC lathe grooving program.Fanuc cnc programming for Grooving.CNC lathe programming. O0006;(Grooving)N1;T0;G40;G28 U0 W0;G54;G92 S200;G95 F0.06 T0909;G96 S120 M04;G00 Z-14.0;G00 X102;G01 X95 M08;G00 X300.0;T0;G40;G28 U0 W0;M01;M30; Explanation-cnc programming g code & M codes-CNC lathe grooving program Read more… - CNC program for taper turning pdf

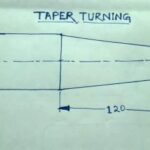

CNC program for taper turning pdf-Learn CNC program for taper turning for both Fanuc and Siemens. Program-Taper turning cnc code- Oi-TB O0005(Taper turning); N1; T0; G40; G28 U0 W0; G54; G92 S1000; G95 F0.2 T0101; Read more…

CNC program for taper turning pdf-Learn CNC program for taper turning for both Fanuc and Siemens. Program-Taper turning cnc code- Oi-TB O0005(Taper turning); N1; T0; G40; G28 U0 W0; G54; G92 S1000; G95 F0.2 T0101; Read more… - CNC Programming for Turning | Turning program for Beginners

CNC programming examples for turning-CNC Programming for Turning.This is the basic example of turning programming.Beginners can get the complete idea about the turning operation. Program(Fanuc Oi-TB) O0001(Plain Turning); N1; T0; G40; G30 P3 U0 W0; Read more…

CNC programming examples for turning-CNC Programming for Turning.This is the basic example of turning programming.Beginners can get the complete idea about the turning operation. Program(Fanuc Oi-TB) O0001(Plain Turning); N1; T0; G40; G30 P3 U0 W0; Read more… - CNC machining process flow chart | Lathe machine flow chart

learn CNC machining process flow chart-CNC machining process flow diagram. Flow chart Explanation step by step- Steps of Flow chart Explanation Start Start the Machine Load the raw material Load the raw material on machine/Hold Read more…

learn CNC machining process flow chart-CNC machining process flow diagram. Flow chart Explanation step by step- Steps of Flow chart Explanation Start Start the Machine Load the raw material Load the raw material on machine/Hold Read more… - CNC facing program

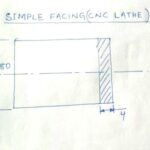

CNC facing program-Simple Facing CNC Lathe Program Example.-Fanuc O0001(CNC Facing Program) N1; T0; G40; G28 U0 W0; -(X-U,Z-W) G54; G92 S1000; G95 F0.2 T0101; G96 S280 M04; G00 Z5.0; G00 X82.0; G01 Z2.0 ; G01 Read more…

CNC facing program-Simple Facing CNC Lathe Program Example.-Fanuc O0001(CNC Facing Program) N1; T0; G40; G28 U0 W0; -(X-U,Z-W) G54; G92 S1000; G95 F0.2 T0101; G96 S280 M04; G00 Z5.0; G00 X82.0; G01 Z2.0 ; G01 Read more… - Basic of CNC programming | Basic program writing

This is the basic of CNC Programming .Here you will get a complete idea about the programming for CNC machine.Here you will learn about the codes,defining part of the program,Operation part of the program and Read more…

This is the basic of CNC Programming .Here you will get a complete idea about the programming for CNC machine.Here you will learn about the codes,defining part of the program,Operation part of the program and Read more…

0 Comments