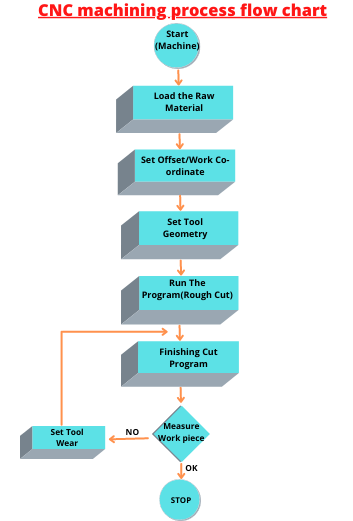

learn CNC machining process flow chart-CNC machining process flow diagram.

Flow chart Explanation step by step-

| Steps of Flow chart | Explanation |

| Start | Start the Machine |

| Load the raw material | Load the raw material on machine/Hold by chuck. |

| Set offset/work co-ordinate | Touch the tip of tool(Master tool) on face of the work piece and set the Z value Zero.Again touch the tip of the tool on OD of work piece and set X value as OD value.(G54 X_Z_.).For details read-Basic of cnc programming. |

| Set tool Geometry | Same like master tool set offset for all other tools.For details of Tool geametry read-Basic of CNC programming. |

| Run the program | After Offset setting run the program for rough cut with high feed. |

| Finishing cut program | After rough cut measure the job and give the finishing cut. |

| Measure Workpiece | After finishing cut measure the workpiece.If the material not removed completely then we have to set Tool wear. |

| Tool wear | Set tool wear if material not removed completely.After set the tool wear again run finishing cut program.For details of tool wear read-Basic of cnc programming. |

| Stop | Again measure the job and remove from chuck |

0 Comments