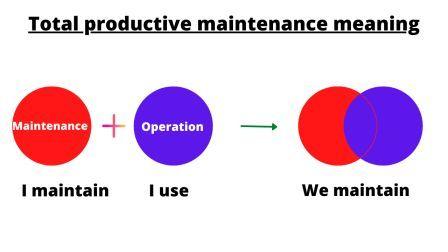

Total productive maintenance meaning a process to enhance the productivity.

Definition of total productive maintenance Maintain a system or machine by both Operator and Technician is called Total Productive maintenance.(Both operation and maintenance department.)

Total productive maintenance meaning Total productive maintenance(TPM) is a process of identify and eliminate the loss.

Benefits of TPM It Improves the business result. Creates a pleasant work environment. Improves quality of peoples. Purpose of TPM Purpose of TPM 8 Pillar Of TPM Focused Improvement Autonomous Maintenance Planned Maintenance Education & Training Development management Quality maintenance Safety,Health and Environment TPM in Office Focused Improvement This Pillar focused on Zero Loss by efficient utilization of equipment,human resources,materials and energy.

Major Losses in Production system. Equipment Failure Shutdown Process failure Normal Production loss Abnormal production loss Quality defect Production adjustment Reprocessing OEE-Overall Equipment effectiveness The efficiency of equipment is measured in terms of OEE.

OEE calculation- Based on Availability,Performance rate and quality rate of the equipment.

Autonomous Maintenance This is the process of developing the operator to be able to take care of routine maintenance.

This pillar prevent the equipment deterioration.

Maintenance Steps Perform initial cleaning. Equipment inspection. Process inspection. Maintain 5S. Address any abnormal in equipment. Planned Maintenance The purpose of the pillar is to maintain the equipment in best condition for uninterrupted production.

This can be developed by following steps.

Perform periodic maintenance. Perform predictive maintenance. Evaluate the current condition of equipment. Education & Training This pillar improve the potential of every employee.It enhance the knowledge and skills of worker.

Development management This process reduce the future maintenance cost.This activity is taken in design and development stage.

If some error occur in machine continuously then it can be remove by changing the design.

Quality maintenance This pillar is to achieve zero customer complaints and defects.

Safety,Health and Environment This pillar helps to eliminate human error and accident.And also responsible to create pollution free environment.

The main objective of this pillar is to achieve “ZERO ACCIDENT”.

TPM in Office This pillar indicates the practice of TPM in administrative office and all support office.

The main purpose of this pillar is to backing up the production activity.

For More Details Click Here

CNC Lathe O&M

FRL unit | Working principle & function of frl unit by Rajib

March 20, 2024 Servo motor | Working principle,function and component by Rajib

March 19, 2024 Hydraulic motor | Working principle,types,HSN code by Rajib

March 18, 2024 Pneumatic cylinder | Parts,working principle and HSN Code by Rajib

March 17, 2024 Hydraulic cylinder | Working principle,types & hsn code by Rajib

March 16, 2024 Control valves | Working principle,Types and characteristics by Rajib

March 15, 2024 LVDT | Working Principle,Application & construction by Rajib

March 14, 2024 Thermocouple | Working principle,types & application by Rajib

March 13, 2024 Thermistor | Working principle ,Application & types by Rajib

March 12, 2024 Pressure sensors types,principle and examples. by Rajib

March 11, 2024 Petroleum oil chemical formula | Petrol and Diesel formulae by Rajib

March 10, 2024 Strain gauge pressure sensor | Principle,use and diagram by Rajib

February 23, 2024 AIR COMPRESSOR | Air compressor tank machine price,parts,types by Rajib

January 11, 2024 Gear motor | Gear motor types | gear motor hsn code by Rajib

January 8, 2024 PASCAL LAW and its application | Pascal law derivation pdf by Rajib

January 2, 2024 Bernoulli’s principle | Bernoulli principle applications by Rajib

December 9, 2023 Compressed air | Compressed air system and components by Rajib

October 7, 2023 Bimetallic strip works on the principle of by Rajib

October 2, 2023 Solenoid,Valve,coil,switch,lock,formula,magnetic field and diagram by Rajib

September 20, 2023 Power Electronics application and Scope by Rajib

August 24, 2023 Shutoff valve | Shutoff valve Symbol | Stop valve by Rajib

July 31, 2023 Viscosity | Unit,Formula,coefficient,dimension,law and index of Viscosity by Rajib

July 16, 2023 How to calculate hydraulic cylinder force? by Rajib

July 11, 2023 FRL unit parts name | FRL unit working principle by Rajib

July 1, 2023 Block diagram of a closed loop control system by Rajib

June 26, 2023 Hydraulic actuators | Types of hydraulic actuators by Rajib

June 22, 2023 Difference between Pneumatics and Hydraulics by Rajib

June 14, 2023 Filter in hydraulic system | Strainer and Return line filter by Rajib

June 13, 2023 Pump cavitation | Hydraulic pump cavitation definition by Rajib

June 8, 2023 Function of flow control valve | Flow control valve working principle by Rajib

June 6, 2023 Direction control valve in hydraulic system by Rajib

May 30, 2023 Symbol of pressure gauge | Specification of pressure gauge by Rajib

May 26, 2023 Symbol of globe valve | P & ID Gate,ball,butterfly valve symbol by Rajib

May 23, 2023 Electric symbol for motor | 3 phase motor symbol by Rajib

May 22, 2023 Electrical symbol for relay | Control relay symbol | Coil symbol electrical by Rajib

May 22, 2023 Pressure reduction valve symbol | Hydraulic symbol of Pressure reduction valve by Rajib

May 20, 2023 Symbol of pressure switch | Pressure switch symbol in hydraulic system by Rajib

May 16, 2023 4/2 directional control valve symbol by Rajib

May 6, 2023 4/3 directional control valve symbol and working principle by Rajib

April 23, 2023 Symbol for pressure relief valve | Working principle of Pressure relief valve by Rajib

April 13, 2023

0 Comments