CNC turning cycle program.Siemens/Fanuc cnc turning cycle programming examples.

How to make turning cycle program…?

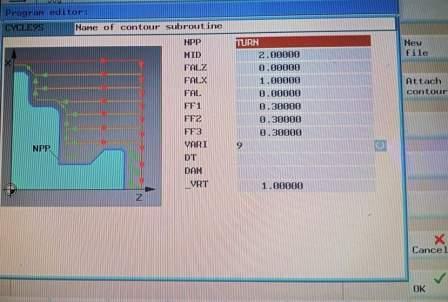

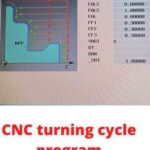

CYCLE95(Siemens-802d)

| Codes | Details |

| NPP | Name of Contour(Ex:-TURN). |

| MID | In feed depth(It is the depth of cut. Ex;- If it is 0.2,then 4mm diameter will remove per each revolution ) |

| FALZ | Finishing allowance along Z axis.(Ex:- If its value is 0.3 then 0.3mm will be left for finishing) |

| FALX | Finishing allowance along X axis.(Ex:- If its value is 0.3 then 0.3mm will be left for finishing) |

| FAL | Finishing allowance suitable for contour.(For any profile) |

| FF1 | Feed rate for roughing without relief cut.For roughing tool movement in Z axis per revolution.Without relief cut indicates that tool will return without touching. |

| FF2 | Feed rate for plunging into relief cut.Plunging indicates when the tool taking depth. |

| FF3 | Feed rate for fininshing during roughing. |

| VARI | Operation.Different code for different opration.(Ex:- 9 is for roughing.) |

| DT | Dwell to chip break. |

| DAM | Path for roughing. |

| VRI | Retract path from. |

Example-

Main Program(Siemens(802d)

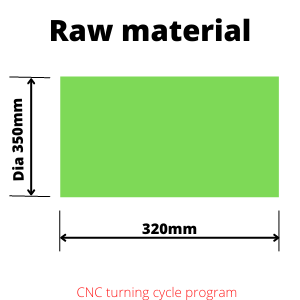

| G90 G95; M03 S90; T1D1; G00 X355 Z2; CYCLE95(“TURN“2.00000, 0.00000, 1.00000, 0.00000 0.30000, 0.30000, 0.30000, 9, , ,1.00000); G00 X360; G00 Z2.0; M30; |

Explanation

| G90 G95; M03 S90; T1D1; | For G code and M code Click here |

| G00 X355 Z2; | Tool will move rapidly to safety distance in X and Z axis. |

| CYCLE95(“TURN“2.00000, 0.00000, 1.00000, 0.00000 0.30000, 0.30000, 0.30000, 9, , ,1.00000); | This is the call of Soft program-TURN |

| G00 X360; G00 Z2.0; M30; | Rapid return to safety distance . |

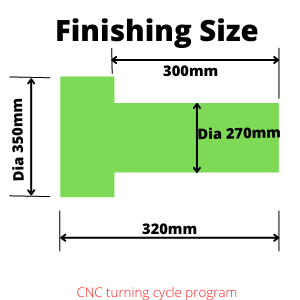

Soft Program(Siemens 802d)-Name should be:- TURN

This program will be called in main program for turning cycle.

| G01 X270 Z0.0; G01 X270 Z-300 G1 X350 M17; |

0 Comments