CNC lathe machine operation & maintenance. Learn cnc programming and how to repair.

Maintenance/Repair of CNC Lathe

CNC LATHE ERROR

| PARTS | ERROR |

| Tail Stock | 1-Tail stock vibration. 2-Turning not smooth. 3-Taper cutting.(tail stock,X axis taper wedge/turret center out) 4-Chattering . 5-Quill movement error. 6-Tail stock locking on bed problem.(Hyd/bolting) 7-Tail stock oil leakage.HYD 8-Tail stock pressure problem. |

| Chuck | 1-Chuck holding problem. 2-Sound from chuck belt drive during braking. 3-Chuck speed getting slow during cutting feed. 4-Jaw not working.Openning/Closing. 5-Jaw not holding rigidly. 6-Rotation not uniform. |

| Axis | 1-X axis brake/Holding problem. 2-Taper wedge. 3-Ball screw/nut replacement. |

| Steady | 1-Abnormal sound/Bearing damage 2-Holding/Locking on bed 3-Arm movement. |

| Lubrication Error | 1-Lubrication fail 2-Low oil level |

| Chips Conveyor | 1- Jamming. 2-Over load error. 3-Tripping. |

| Hydraulic Unit | 1-Over Heating 2-More noise 3-Low Pressure 4-Low oil level |

Solutions Coming Soon….

- Basic of CNC programming | Basic program writing

by RajibThis is the basic of CNC Programming .Here you will get a complete idea about the programming for CNC machine.Here you will learn about the codes,defining part of the program,Operation part of the program and Read more…

by RajibThis is the basic of CNC Programming .Here you will get a complete idea about the programming for CNC machine.Here you will learn about the codes,defining part of the program,Operation part of the program and Read more… - CNC facing program | CNC Lathe facing programming

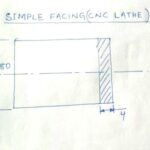

by RajibCNC facing program-Simple Facing CNC Lathe Program Example.-Fanuc. O0001(CNC Facing Program) N1; T0; G40; G28 U0 W0; -(X-U,Z-W) G54; G92 S1000; G95 F0.2 T0101; G96 S280 M04; G00 Z5.0; G00 X82.0; G01 Z2.0 ; G01 Read more…

by RajibCNC facing program-Simple Facing CNC Lathe Program Example.-Fanuc. O0001(CNC Facing Program) N1; T0; G40; G28 U0 W0; -(X-U,Z-W) G54; G92 S1000; G95 F0.2 T0101; G96 S280 M04; G00 Z5.0; G00 X82.0; G01 Z2.0 ; G01 Read more… - CNC machining process flow chart | Lathe machine flow chart

by RajibLearn CNC machining process flow chart-CNC machining process flow diagram. Flow chart Explanation step by step- Steps of Flow chart Explanation Start Start the Machine Load the raw material Load the raw material on machine/Hold Read more…

by RajibLearn CNC machining process flow chart-CNC machining process flow diagram. Flow chart Explanation step by step- Steps of Flow chart Explanation Start Start the Machine Load the raw material Load the raw material on machine/Hold Read more… - CNC Programming for Turning | Turning program for Beginners

by RajibCNC programming examples for turning-CNC Programming for Turning.This is the basic example of turning programming.Beginners can get the complete idea about the turning operation. Program(Fanuc Oi-TB) Program Explanation- N1 Sequence number. T0 Tool wear cancel.For Read more…

by RajibCNC programming examples for turning-CNC Programming for Turning.This is the basic example of turning programming.Beginners can get the complete idea about the turning operation. Program(Fanuc Oi-TB) Program Explanation- N1 Sequence number. T0 Tool wear cancel.For Read more… - CNC program for taper turning pdf

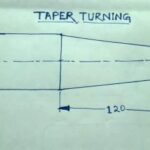

by RajibCNC program for taper turning pdf-Learn CNC program for taper turning for both Fanuc and Siemens. Program-Taper turning cnc code- Oi-TB Taper turning Program Explanation Codes Explanation N1 Sequence number. T0 Tool wear cancel.This will Read more…

by RajibCNC program for taper turning pdf-Learn CNC program for taper turning for both Fanuc and Siemens. Program-Taper turning cnc code- Oi-TB Taper turning Program Explanation Codes Explanation N1 Sequence number. T0 Tool wear cancel.This will Read more… - CNC lathe grooving program | CNC Programming For Beginners

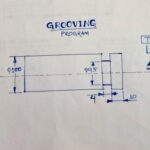

by RajibCNC lathe grooving program.Fanuc cnc programming for Grooving.CNC lathe programming. O0006;(Grooving)N1;T0;G40;G28 U0 W0;G54;G92 S200;G95 F0.06 T0909;G96 S120 M04;G00 Z-14.0;G00 X102;G01 X95 M08;G00 X300.0;T0;G40;G28 U0 W0;M01;M30; Explanation-cnc programming g code & M codes-CNC lathe grooving program Read more…

by RajibCNC lathe grooving program.Fanuc cnc programming for Grooving.CNC lathe programming. O0006;(Grooving)N1;T0;G40;G28 U0 W0;G54;G92 S200;G95 F0.06 T0909;G96 S120 M04;G00 Z-14.0;G00 X102;G01 X95 M08;G00 X300.0;T0;G40;G28 U0 W0;M01;M30; Explanation-cnc programming g code & M codes-CNC lathe grooving program Read more… - Radius program in CNC | CNC Lathe Programming

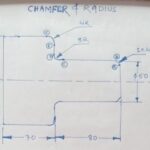

by RajibLearn Radius program in CNC. CNC turning..Fanuc cnc lathe programming examples.Siemens cnc lathe programming examples. CHAMFER COORDINATE(X,Z) RADIUS COORDINATE(X,Z) A:(48,0)B:(50,-1) C:(50,-75)D:(60,-80)E:(92,-80)F:(100,-84) PROGRAM O0007(RADIUS & CHAMFER)N1;G40;T0;G30 U0 W0;G54;G92 S1000;G95 F0.2 T0101;G96 S220 M04;G00 Z2.0;G00 X55.0 M08;G01 Read more…

by RajibLearn Radius program in CNC. CNC turning..Fanuc cnc lathe programming examples.Siemens cnc lathe programming examples. CHAMFER COORDINATE(X,Z) RADIUS COORDINATE(X,Z) A:(48,0)B:(50,-1) C:(50,-75)D:(60,-80)E:(92,-80)F:(100,-84) PROGRAM O0007(RADIUS & CHAMFER)N1;G40;T0;G30 U0 W0;G54;G92 S1000;G95 F0.2 T0101;G96 S220 M04;G00 Z2.0;G00 X55.0 M08;G01 Read more… - CNC turning cycle program

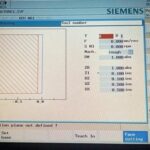

by RajibCNC turning cycle program

by RajibCNC turning cycle program - CNC facing cycle program

by RajibCNC facing cycle program.Fanuc Oi-TB facing cycle.Siemens 802d Facing cycle program. Parameter/Code Details T1 D1 Tool number. F Feed-mm/rev. S M3 RPM,M3 -Clockwise,M4-Counter clockwise. Mach. Machining-Roughing/Finishing. DM Diameter of Job/work piece. Z0 Starting point of Read more…

by RajibCNC facing cycle program.Fanuc Oi-TB facing cycle.Siemens 802d Facing cycle program. Parameter/Code Details T1 D1 Tool number. F Feed-mm/rev. S M3 RPM,M3 -Clockwise,M4-Counter clockwise. Mach. Machining-Roughing/Finishing. DM Diameter of Job/work piece. Z0 Starting point of Read more… - CNC machine operator daily checklistby RajibCNC machine operator daily checklist.How do you maintain a CNC machine?What are the general requirements of CNC machines?

- How do you troubleshoot a Hydraulic system?by RajibHow do you troubleshoot a Hydraulic system.Learn about Hydraulic solenoid valve troubleshooting.Hydraulic pump trouble shooting gude of CNC machine. Hydraulic pump troubleshooting guide Fault Root cause Solution Noise in Pump 1- Coupling problem.It may misaligned.2– Read more…

- CNC machine maintenance checklistby RajibCNC machine maintenance checklist for daily,weekly,monthly,half yearly and yearly inspection. CNC machine daily maintenance checklist Machine parts Checklist Mechanical 1-Ensure that the machine is clean near Chuck or spindle and Bed .2-Check all cover or Read more…

- Safety rules in machine shop | CNC machine shop safetyby RajibSafety rules in machine shop.Safety Precautions in CNC machine.CNC machine equipment safety.Safe operating procedures for machinery. Workshop General Safety Rule These General safety Precautions will help to produce a defect free product and working environment.This Read more…

- Total productive maintenance meaning

by RajibTotal productive maintenance meaning a process to enhance the productivity. Definition of total productive maintenance Maintain a system or machine by both Operator and Technician is called Total Productive maintenance.(Both operation and maintenance department.) Total Read more…

by RajibTotal productive maintenance meaning a process to enhance the productivity. Definition of total productive maintenance Maintain a system or machine by both Operator and Technician is called Total Productive maintenance.(Both operation and maintenance department.) Total Read more… - CNC Lathe machine | Operation & Maintenanceby RajibCNC lathe machine operation & maintenance. Learn cnc programming and how to repair. Maintenance/Repair of CNC Lathe CNC LATHE ERROR PARTS ERROR Tail Stock 1-Tail stock vibration.2-Turning not smooth.3-Taper cutting.(tail stock,X axis taper wedge/turret center Read more…

- Machine shop | Machine shop CNC Lathe toolsby RajibMachine shop is a manufacturing , repair or reconditioning shop of mechanical parts.It contains all types of machines likes drilling,Lathe(turning),boring,shaping,slotting machine. It performs different operations like turning,drilling,milling,boring,slotting,gear hobbing,grinding. Machines list for Machine Shop Manual Lathe Read more…

- Tool box | Hand Tools for machine shopby RajibTool box used in Machine shop or Machine maintenance.Tool box kit for home. Tools List Electric Hand Drill Normally used for making drill hole on machine body,wall and work pieces. Pliers Used in electrical work Read more…

- CNC Lathe machine specificationby RajibCNC Lathe machine specification.CNC turning machine specification. MACHINE RATING1-Machine Length2-Depth3-Height4-Weight5-Coolant capacity6-Coolant pump motor capacity.7-Chip conveyor motor power.8-Chip conveyor width/capacity.9-Control -fanuc/Siemens. CAPACITY1-Chuck size.2-Turning Diameter-Maximum.3-Swing Over Way Covers.4-Swing Over Carriage.5-Maximum Turning Length SPINDLE1-Grease Packed Preloaded Angular Contact Read more…

- CNC Lathe machining parts | CNC lathe machine parts and functionsby RajibCNC Lathe machining parts.CNC lathe machine parts and functions. Contents 1-Chuck2-Main drive/Spindle/Head Stock3-Tailstock4-Steady rest5-Turret6-Control Panel7-Tailstock quill8-Foot switch/Foot Pedal9-Bed10-Hydraulic unit.11-X axis Drive.12-Z axis Drive.13-Coolant tank 14-Chips Conveyor15-Automatic Lubrication Unit-ALU

- Lubrication system in CNC machine | Automatic Lubrication Systemby RajibAutomatic Lubrication System in CNC machine.Motorised lubrication unit. Lubrication pump for cnc machine Pump Type Discharge Driven by Rotary Positive Displacement pump Low discharge Electric Motor Select pump ,pressure range,motor rating and tank size as Read more…

0 Comments