Lathe machine block diagram.Block diagram of cnc machine.Facing,Turning,Grooving.

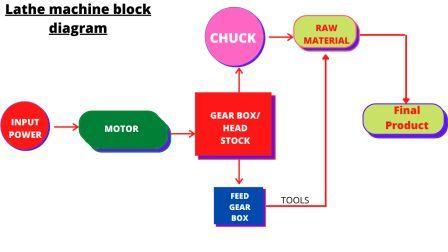

In conventional lathe machine chuck is rotates by gear box/Head stock.Power provided to gear box from electrical motor.Tool post movements is through head stock gear box for feed.

For rapid movement of tool post is through separate electrical motor or by manual handle.

It is an Open Loop Control system.

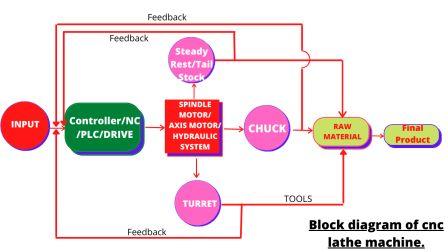

CNC Lathe

For CNC lathe machine control system is close loop.Close loop control system is one where feed back will be provided from every output.

In this machine chuck rpm,tool movement/position,tool post position every feed back will be provided to plc.

| Facing program | Turning program | Taper turning program |

| Grooving Program | Radius program | Turning cycle & Facing cycle |

- CNC facing program | CNC Lathe facing programming

by RajibCNC facing program-Simple Facing CNC Lathe Program Example.-Fanuc. O0001(CNC Facing Program) N1; T0; G40; G28 U0 W0; -(X-U,Z-W) G54; G92 S1000; G95 F0.2 T0101; G96 S280 M04; G00 Z5.0; G00 X82.0; G01 Z2.0 ; G01 Read more…

by RajibCNC facing program-Simple Facing CNC Lathe Program Example.-Fanuc. O0001(CNC Facing Program) N1; T0; G40; G28 U0 W0; -(X-U,Z-W) G54; G92 S1000; G95 F0.2 T0101; G96 S280 M04; G00 Z5.0; G00 X82.0; G01 Z2.0 ; G01 Read more… - CNC machining process flow chart | Lathe machine flow chart

by RajibLearn CNC machining process flow chart-CNC machining process flow diagram. Flow chart Explanation step by step- Steps of Flow chart Explanation Start Start the Machine Load the raw material Load the raw material on machine/Hold Read more…

by RajibLearn CNC machining process flow chart-CNC machining process flow diagram. Flow chart Explanation step by step- Steps of Flow chart Explanation Start Start the Machine Load the raw material Load the raw material on machine/Hold Read more… - CNC Programming for Turning | Turning program for Beginners

by RajibCNC programming examples for turning-CNC Programming for Turning.This is the basic example of turning programming.Beginners can get the complete idea about the turning operation. Program(Fanuc Oi-TB) Program Explanation- N1 Sequence number. T0 Tool wear cancel.For Read more…

by RajibCNC programming examples for turning-CNC Programming for Turning.This is the basic example of turning programming.Beginners can get the complete idea about the turning operation. Program(Fanuc Oi-TB) Program Explanation- N1 Sequence number. T0 Tool wear cancel.For Read more… - CNC program for taper turning pdf

by RajibCNC program for taper turning pdf-Learn CNC program for taper turning for both Fanuc and Siemens. Program-Taper turning cnc code- Oi-TB Taper turning Program Explanation Codes Explanation N1 Sequence number. T0 Tool wear cancel.This will Read more…

by RajibCNC program for taper turning pdf-Learn CNC program for taper turning for both Fanuc and Siemens. Program-Taper turning cnc code- Oi-TB Taper turning Program Explanation Codes Explanation N1 Sequence number. T0 Tool wear cancel.This will Read more… - CNC lathe grooving program | CNC Programming For Beginners

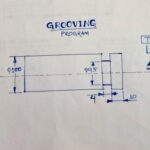

by RajibCNC lathe grooving program.Fanuc cnc programming for Grooving.CNC lathe programming. O0006;(Grooving)N1;T0;G40;G28 U0 W0;G54;G92 S200;G95 F0.06 T0909;G96 S120 M04;G00 Z-14.0;G00 X102;G01 X95 M08;G00 X300.0;T0;G40;G28 U0 W0;M01;M30; Explanation-cnc programming g code & M codes-CNC lathe grooving program Read more…

by RajibCNC lathe grooving program.Fanuc cnc programming for Grooving.CNC lathe programming. O0006;(Grooving)N1;T0;G40;G28 U0 W0;G54;G92 S200;G95 F0.06 T0909;G96 S120 M04;G00 Z-14.0;G00 X102;G01 X95 M08;G00 X300.0;T0;G40;G28 U0 W0;M01;M30; Explanation-cnc programming g code & M codes-CNC lathe grooving program Read more… - Radius program in CNC | CNC Lathe Programming

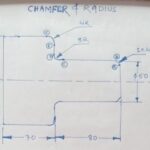

by RajibLearn Radius program in CNC. CNC turning..Fanuc cnc lathe programming examples.Siemens cnc lathe programming examples. CHAMFER COORDINATE(X,Z) RADIUS COORDINATE(X,Z) A:(48,0)B:(50,-1) C:(50,-75)D:(60,-80)E:(92,-80)F:(100,-84) PROGRAM O0007(RADIUS & CHAMFER)N1;G40;T0;G30 U0 W0;G54;G92 S1000;G95 F0.2 T0101;G96 S220 M04;G00 Z2.0;G00 X55.0 M08;G01 Read more…

by RajibLearn Radius program in CNC. CNC turning..Fanuc cnc lathe programming examples.Siemens cnc lathe programming examples. CHAMFER COORDINATE(X,Z) RADIUS COORDINATE(X,Z) A:(48,0)B:(50,-1) C:(50,-75)D:(60,-80)E:(92,-80)F:(100,-84) PROGRAM O0007(RADIUS & CHAMFER)N1;G40;T0;G30 U0 W0;G54;G92 S1000;G95 F0.2 T0101;G96 S220 M04;G00 Z2.0;G00 X55.0 M08;G01 Read more… - CNC turning cycle program

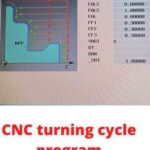

by RajibCNC turning cycle program

by RajibCNC turning cycle program - CNC facing cycle program

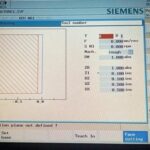

by RajibCNC facing cycle program.Fanuc Oi-TB facing cycle.Siemens 802d Facing cycle program. Parameter/Code Details T1 D1 Tool number. F Feed-mm/rev. S M3 RPM,M3 -Clockwise,M4-Counter clockwise. Mach. Machining-Roughing/Finishing. DM Diameter of Job/work piece. Z0 Starting point of Read more…

by RajibCNC facing cycle program.Fanuc Oi-TB facing cycle.Siemens 802d Facing cycle program. Parameter/Code Details T1 D1 Tool number. F Feed-mm/rev. S M3 RPM,M3 -Clockwise,M4-Counter clockwise. Mach. Machining-Roughing/Finishing. DM Diameter of Job/work piece. Z0 Starting point of Read more… - How do you troubleshoot a Hydraulic system?by RajibHow do you troubleshoot a Hydraulic system.Learn about Hydraulic solenoid valve troubleshooting.Hydraulic pump trouble shooting gude of CNC machine. Hydraulic pump troubleshooting guide Fault Root cause Solution Noise in Pump 1- Coupling problem.It may misaligned.2– Read more…

- Safety rules in machine shop | CNC machine shop safetyby RajibSafety rules in machine shop.Safety Precautions in CNC machine.CNC machine equipment safety.Safe operating procedures for machinery. Workshop General Safety Rule These General safety Precautions will help to produce a defect free product and working environment.This Read more…

- Lathe machine block diagram,CNC lathe

by RajibLathe machine block diagram.Block diagram of cnc machine.Facing,Turning,Grooving. In conventional lathe machine chuck is rotates by gear box/Head stock.Power provided to gear box from electrical motor.Tool post movements is through head stock gear box for Read more…

by RajibLathe machine block diagram.Block diagram of cnc machine.Facing,Turning,Grooving. In conventional lathe machine chuck is rotates by gear box/Head stock.Power provided to gear box from electrical motor.Tool post movements is through head stock gear box for Read more… - CNC Lathe machine | Operation & Maintenanceby RajibCNC lathe machine operation & maintenance. Learn cnc programming and how to repair. Maintenance/Repair of CNC Lathe CNC LATHE ERROR PARTS ERROR Tail Stock 1-Tail stock vibration.2-Turning not smooth.3-Taper cutting.(tail stock,X axis taper wedge/turret center Read more…

- Machine shop | Machine shop CNC Lathe toolsby RajibMachine shop is a manufacturing , repair or reconditioning shop of mechanical parts.It contains all types of machines likes drilling,Lathe(turning),boring,shaping,slotting machine. It performs different operations like turning,drilling,milling,boring,slotting,gear hobbing,grinding. Machines list for Machine Shop Manual Lathe Read more…

- CNC Lathe | Operation & Maintenance of CNC latheby RajibWhat is cnc lathe?.Cnc lathe parts.Cnc lathe tools. Introduction of CNC lathe machine CNC Operation/Programming CNC maintenance/Repair 1-Basic Of CNC Programming.2-Facing program.3-Turning Program.4-Taper Turning.5-Grooving operation.6-Radius program.7-Turning Cycle.8-Facing Cycle. 1-Operator Daily Checklist.2-CNC maintenance Checklist.3-Safety Rules of Read more…

- CNC Lathe machine specificationby RajibCNC Lathe machine specification.CNC turning machine specification. MACHINE RATING1-Machine Length2-Depth3-Height4-Weight5-Coolant capacity6-Coolant pump motor capacity.7-Chip conveyor motor power.8-Chip conveyor width/capacity.9-Control -fanuc/Siemens. CAPACITY1-Chuck size.2-Turning Diameter-Maximum.3-Swing Over Way Covers.4-Swing Over Carriage.5-Maximum Turning Length SPINDLE1-Grease Packed Preloaded Angular Contact Read more…

- CNC Lathe machining | CNC control panel | Operation of cnc lathe machineby RajibCNC Lathe machining.CNC control panel.Machine Cycle.Program Function.Machine Start up.cnc lathe machine operation. SAFETY INSTRUCTION . Follow these safety instruction before turn ON the machine. Use safety glasses to protect eyes. Safety shoes must required. Tie, Read more…

- How to set up a CNC Lathe | Installation of CNC Latheby RajibHow to set up a CNC Lathe.Installation and commissioning of lathe machine.Foundation and Levelling. Installation Procedure. Foundation Machine Inspection Machine Placement Leveling Grouting Foundation As per layout drawing make drill hole.Place the foundation bolt and Read more…

- How CNC machine works | CNC Latheby RajibHow CNC machine works. Electrical Components Mechanical components NC/PLC Chuck Motor Drive Spindle Servo Motor Turret Sensors Tailstock Pressure Switch Saddle Operator Panel/Key board/Display Steady Rest Power Supply Belt Drive/Pully Encoder Coolant Pump Limit Switch Read more…

- CNC lathe chuck | Hydraulic chuck | Chuck removal

by RajibCNC lathe chuck Safety. Use proper lifting equipment or crane to load a job. Check the jaw pressure and maintain required value. Grease properly at grease point given. Use crane to remove the chuck from Read more…

by RajibCNC lathe chuck Safety. Use proper lifting equipment or crane to load a job. Check the jaw pressure and maintain required value. Grease properly at grease point given. Use crane to remove the chuck from Read more… - Turret | Turret meaning | Turret cncby RajibTurret of cnc lathe machine. Turret meaning It’s a tool station which can index any tool for operation.It’s clamp and unclamp are controlled by hydraulic. IT can be rotate by hydro motor or servomotor. Components Read more…

- Tailstock live center | CNC Latheby RajibTailstock Live center.Dead Center Vs Live Center. LIVE CENTER DEAD CENTER 1- It rotates. 1-It does not rotates.Work piece rotates about it. 2- It mounted on bearing. 2- Its only a metal shaft with point. Read more…

- Lathe head stock | CNC Lathe Head Stockby RajibIn CNC Lathe Head Stock is only the main spindle without Gear Box.The spindle is driven by AC servo motor.Power transmitted to spindle from motor by V belt. Difference Between CNC & Manual Lathe head Read more…

- How to start cnc machine | CNC Latheby RajibHow to start cnc Lathe machine?How to operate cnc lathe machine?. Start up Procedure of CNC Lathe machine. Operating Procedure Practical

- Lathe machine | Operation and Maintenance of Lathe Machineby RajibLathe machine operations , maintenance and tools. Conventional Lathe Machine Error Head Stock Breakdown Chuck is getting low speed during more cutting feed. Gear shifting problem-Low/High Rpm. Rpm selection problem. Chuck not rotating in Forward/Reverse Read more…

- Cutting tools in a workshop | Cutting tools for metalsby RajibCutting tools in a workshop.List of cutting tools used in work shop. Single Point Cutting tools Multipoint cutting tools. Band saw Circular saw Grinding wheel Hacksaw Tin snips Air shears Oxy acetylene torch Cutting tool Read more…

- Tool wear types | CNC troubleshootingby RajibTool wear types.CNC troubleshooting for turning tool.Tool wear and tool life.What is tool wear? Breakage or too short tool life. To reduce breakage and reduce short tool life ,we need to reduce cutting data. Reduce Read more…

0 Comments